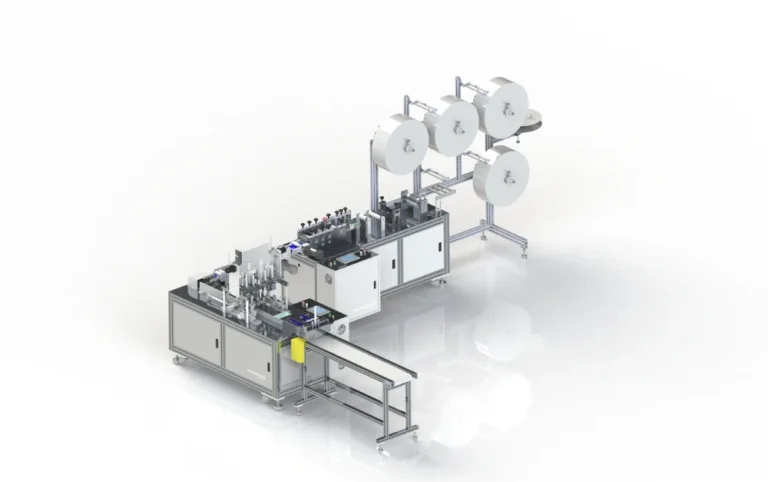

Maskmaker PFF

Maskmaker PFF is the fastest PFF2 / KN95 mask making machine on the market. It produces fully automatically and delivers complete masks, with high resistance, according to the most demanding manufacturing requirements, with low human intervention (no contamination) and almost no material loss in its manufacturing process.

SPECIFICATIONS

INCLUDED ITEMS

| Technology | ultrasound |

| powers | 2 of 2000W 20 kHz for the elastic module 1 of 1500W 15kHz for soldering roller 1 of 1500W 15kHz for mask bend welding |

| Mask model | PFF2 or KN95 standard mask |

| Performance | Up to 80 to 100 masks per minute |

- Professor module for up to 5 TNT roller supports with sensors;

- Mask shaping module with nose clip insertion and cutting, logo engraving and initial cutting;

- Elastic insert module with cut-to-size and simultaneous 4-point soldering;

- Mask bend module with bottom weld and end cut;

- Mask and Burr Separation Module;

- Software for simultaneous operation of all modules with management of the entire sensing system of the equipment;

- Prepared for Industry 4.0 integrations

- Maximum diameter of non-woven rolls: from 500 to 600 mm

- Maximum width of non-woven rolls: 250 mm

- Number of TNT rolls: up to 5 units

- Clip roll max outer diameter: 350 mm

- Clip roll inner diameter: 105 to 200 mm

- Clip Dimensions: 1 x 3 to 5 mm

- Number of rolls Nose Clip Wire: 1 unit

- Maximum outside diameter of elastic roll: 200 mm

- Inner diameter of elastic roll: 16 to 40 mm

- Elastic width: from 3 to 5 mm

FREQUENTLY ASKED QUESTIONS

THE MAIN QUESTIONS

The advantages are many, but let’s list the most important ones:

- Manufactures PFF2 masks that meet the most demanding standards;

- It has high ultrasonic welding power reaching 2,000W and 1,500W;

- Its high power delivers a weld that resists the traction specified in the most diverse standards with safety and stability, that is, the elastics do not loosen;< /span>

- Comes with integrated and synchronized mask body making and elastic insertion modules, which is an advantage over competing solutions that are semi-automatic ;

- The integrated solution uses fewer operators and reduces human intervention and consequent product contamination;

- Its manufacturing flow is constant and stable, with a speed capable of manufacturing between 80 and 100 masks per minute, which is 2x more than competitors, with very low or even no loss;

- Delivers great mask manufacturing stability, no product loss and a rework rate between 2 and 3 times lower than competing machines;< /span>

- Can receive important accessories such as nose clip sponge insert and ink jet printer;

- Allows insertion of logo for manufacturing custom masks;

- Equipped with electronic devices that allow connection to software and IOT systems for remote operation monitoring – Industry 4.0;

- The machine truly complies with Brazilian safety standards NR12 with electrical and mechanical protections for operator safety.

Ultrasonic welding is a welding process that uses high-frequency sound waves to join two or more materials together. The technique consists of applying a specific frequency of sound waves (generally between 20 kHz and 50 kHz) to the materials to be welded. These sound waves create mechanical vibrations that cause friction and heat at the point of contact of the materials, which leads to the melting and welding of the materials.

Ultrasonic welding is widely used to weld thin and delicate materials such as plastics, fabrics and non-ferrous metals. Furthermore, the technique is known to be accurate, fast and efficient, and not to cause damage to surrounding materials. Ultrasonic welding is also widely used to produce electronic components, medical devices, clothing and other products.

Ultrasonic welding and heat welding are two different techniques used in the manufacture of surgical masks. The advantages of ultrasonic welding over heat welding are:

- Precision: Ultrasonic welding is capable of welding fabrics with high precision without causing damage to surrounding tissues. Heat welding, on the other hand, can cause damage to these fabrics such as shrinkage, deformation or burning. This can affect the accuracy and safety of surgical masks.

- Versatility: Ultrasonic welding can be used to weld a variety of fabrics, including fine and delicate fabrics, which is important for the production of surgical masks, whereas in heat welding, there may be damage to the materials, compromising the mask manufacturing process.

- Process hygiene: while ultrasonic welding does not promote contamination in fabrics, heat welding can cause contamination with particles in the air, and compromise the quality and safety of surgical masks.

- Low cost: Ultrasonic welding requires little maintenance and has a long service life, which can result in low operating costs, while heat requires more maintenance due to the heat generated in the system.

CHOOSE THE LANGUAGE

CHOOSE THE LANGUAGE