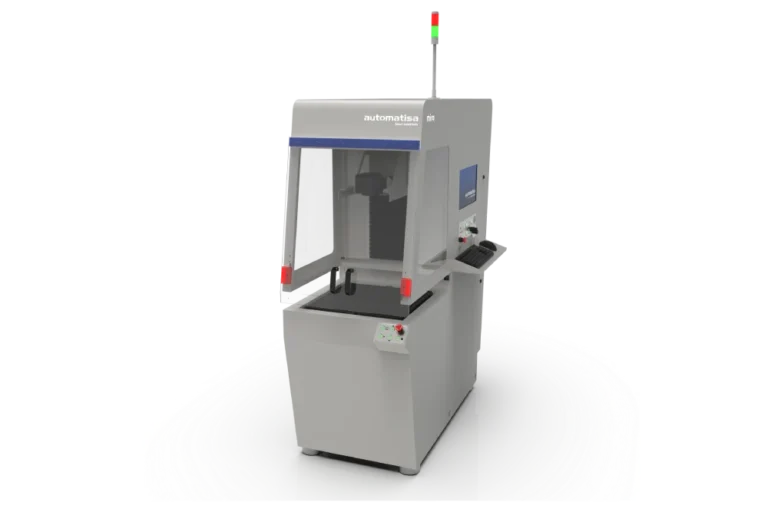

Acrila 1525

The Acrila is a laser cutting machine that was developed especially for cutting processes of non-metallic products, but when equipped with the KCM system it allows the cutting of thin metal sheets. Its most important differential is the speed, robustness and very high quality of cutting finish. That’s because it is equipped with high-performance Japanese servo motors that are faster and more accurate than any other type of motor. Every detail in Acrila has been designed to be easy to use, have low maintenance requirements and be very durable. It is recognized for being the medium power machine that delivers the best acrylic cut on the market.

SPECIFICATIONS

INCLUDED ITEMS

OPTIONAL ACCESSORIES

EXCLUSIVE TECHNOLOGIES

| Laser Type | CO₂ |

| Available powers | 1 or 2 heads of 100W or 150W |

| Workspace | 2500 x 1690 mm up to 2500 x 1500 mm |

- Machine;

- Operation software in Portuguese;

- Computer;

- Electric control cabin and PC support;

- Japanese servomotors;

- Fume extractor;

- Anodized aluminum knife table;

- Cooling chiller;

- Pneumatic system with coalescing filter;

- Protection according to the NR12 standard;

- Installation and training service;

- Autosa Standard Guarantee.

- Beehive table;

- Additional smoke extractors;

- Focusing lenses for special applications;

- Cooling for electronic panel;

- System Automatisa Intelligent Positioning System;

- Head for cutting thin metal sheets.

Available for Acryla 1525

SPIA is the Automatisa Intelligent Positioning System specially developed to allow cuts of pre-printed materials, based on reference points that accompany the printing. The system makes it possible to make precise cuts around a print, without position templates and without errors caused by manual templates. Check out the video.

KCM is a special head for metal cutting, which allows to increase the capacity of the machine for cutting stainless steel, carbon steel and galvanized sheet with the better finish and economy. Through it, it is possible to make cuts of 1.8 to 2mm of carbon steel, 1.2 to 1.5mm of stainless steel and 0.8 to 1.2mm of galvanized sheet. Check out the video.

FREQUENTLY ASKED QUESTIONS

THE MAIN QUESTIONS

Since its conception, Acrila was designed for those companies that need very well-made cuts and that do not want or can do manual polishing operations. For this reason, we have developed a handling system that allows a very bright cut, similar to that of high power machines (500W or 1KW), but possible to obtain with only 150W. Driven by Japanese servomotors makes the movement fast, precise, but smooth. The softness makes the acrylic remain shiny and the entrepreneur can enjoy greater profits with his equipment.

There are countless advantages of acquiring an Acrila, here are some more striking ones:

- It is a professional machine with affordable price;

- It can receive accessories such as SPIA and Metal Cutting Head that make it a multi-material equipment and a super profitable investment;

- The metal cutting system is the only one that allows cutting of thin galvanized sheet, in addition to stainless and carbon steel;< /li>

- Lenses and mirrors last up to 4x longer than other machines on the market;

- The exhaust system accompanies the cutting bridge and ensures suction homogeneity anywhere on the work table;

- Its high-performance engines deliver up to 30% more movement speed;

- It has numerous security systems and meets all NR12 security standards; when equipped with a protective curtain or power cut.

- The table is flexible, with very durable anodized aluminum knives that are removable and easy to clean;

- Easy access from either side of the machine, increasing productivity;

- It is manufactured in Brazil and can be purchased with subsidized credit lines;

- It has the “Automatisa” quality seal with a real guarantee and remote and on-site technical support.

Because it is manufactured in Brazil, you can buy it in installments of up to 10 years, with up to a 2-year grace period through government-subsidized lines such as: Proger, BNDES Finame, BNDES Card. But it is also possible to acquire by leasing-type financing; financing for cash flow and working capital. These lines can finance most or all of your equipment. Our team of experts will inform you of every available alternative.

CHOOSE THE LANGUAGE

CHOOSE THE LANGUAGE