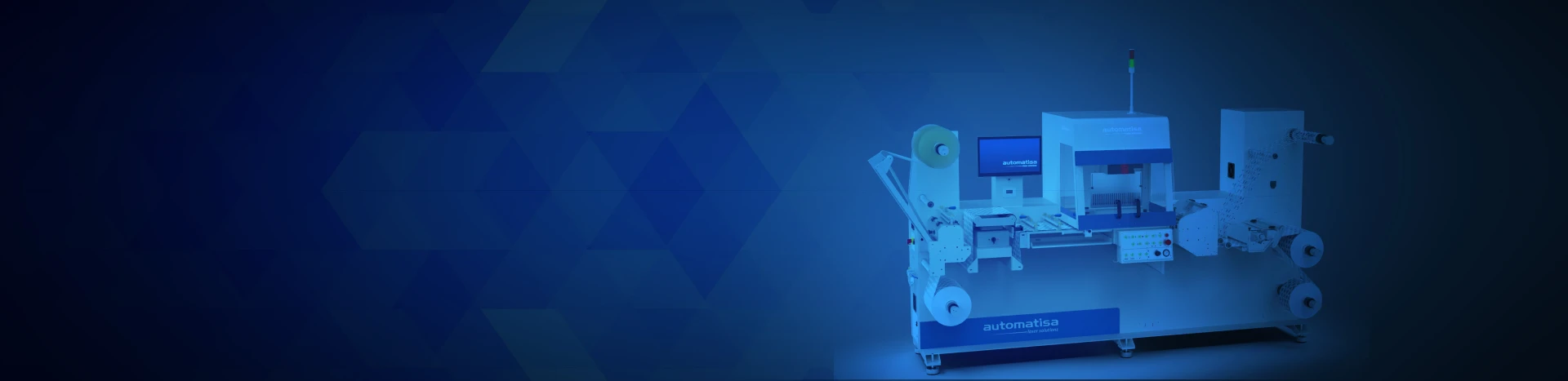

Mira Graph

The Mira Graph is a digital laser cutting, half cutting and perforating machine for labels and labels. Developed to meet the need for digitization in the finishing processes of the labels and labels industry, the Mira Graph is a multifunctional, super flexible equipment that allows finishing to be carried out very easily, at low cost and with a high return on investment.

Laser technology for finishing labels and tags has several advantages such as: precision in cutting; speed in the process between development and obtaining ready-made parts for production; versatility of the type of media processed, being able to cut materials such as bopp, metallic bopp, coated paper, among other adhesives; low cost, as in addition to low maintenance, the machine only consumes electricity; cutting quality, even in complex geometries.

Therefore, Mira Graph has been conquering the labels and tags market, given the excellent cost-benefit ratio with a quick return on investment.

SPECIFICATIONS

INCLUDED ITEMS

OPTIONAL ACCESSORIES

| Laser Type | CO₂ |

| Available powers | 100W; 150W; 250/300W; |

| Workspace | Model 3E: Media width: Up to 200 mm Cutting area: 200 x 200 mm Model 3E: Media width: Up to 330 mm Cutting area: 350 x 350 mm |

| Exclusive Technologies | Automation by QRCode |

- Machine;

- Operation software in Portuguese;

- Computer;

- Unwinder shaft;

- Splicing table;

- Vacuum table for cutting;

- Rewinder shaft;

- Skeleton axis;

- Coil Trimmer;

- Fume extractor;

- Protection according to the NR12 standard;

- Installation and training service;

- Autosa Standard Warranty.

- Cold laminator;

- Edge aligner;

- Cut collection box;

- Additional rewind shaft;

- QRCode automation system;

- Focusing Lenses (model 2E);

- Cooling for electronic panel

FREQUENTLY ASKED QUESTIONS

THE MAIN QUESTIONS

Yes, metallic bopp is a very easy media to be cut by Mira Graph and does not offer any additional difficulty.

Cutting speed depends on 3 factors:

- the type of media: the more sensitive the laser, the faster the cutting speed of the drawing trajectories;

- of cutting geometry: the larger and simpler the geometries, the easier it is to cut;

- the number of vertical stripes of labels that will be present on the roll: the fewer stripes, the faster to cut;

A 100W machine, for example, cuts materials such as polyester at approximately 30m/min or more; bopp at 10 or 12 m/min or more. But this data is variable according to the above elements.

Yes. Mira Graph allows precise adjustment of cutting intensity, so there are no problems with the roll liner that hinder the next process, which is labeling.

Because it is manufactured in Brazil, you can buy it in installments of up to 10 years, with up to a 2-year grace period through lines subsidized by the government such as: Proger, BNDES Finame, BNDES Card. But it is also possible to acquire by leasing-type financing; financing for cash flow and working capital. These lines can finance most or all of your equipment. Our team of experts will inform you of every available alternative.

We do not recommend cutting materials such as PVC, such as vinyl. The laser cutting of materials with PVC, especially the element Chlorine, results in a hydrochloric gas, which, in addition to being toxic for the operator, causes all the metal parts of the equipment to corrode.

If your application requires cutting PVC, you must take extra care, such as using protective masks with adequate filters for operating the equipment, increasing the exhaustion of gases produced and cleaning with very frequently. Still, the corrosion process will remain. It is also important to know that electronic boards and other devices can suffer damage that are not covered by warranty policies.

There are several advantages, such as:

- You can keep a multitude of digital designs to cut whenever you want without taking up space with physical knives;

- Crop adjustment takes a few seconds and does not require much operator knowledge or experience;

- The cutting intensity setting is stable and allows for a smooth process and no loss of product;

- The cutting geometry can be super complex as the laser executes drawings very easily;

- It is possible to perform multi-processes on the machine, such as: full cut, half cut, perforation, engraving, etc,

- The machine’s consumables are minimal, which further favors the return on investment;

Among other advantages associated with a fully digital process.

CHOOSE THE LANGUAGE

CHOOSE THE LANGUAGE