ID Laser CO₂

ID Laser CO2 line laser engravers are highly accurate and versatile machines that use a CO2 laser beam to engrave, cut (thin materials) and mark a variety of materials including wood, leather, adhesives, acrylic, glass, and more. others.

Each model of Automatisa’s line of engravers was designed to facilitate use in some special applications, such as:

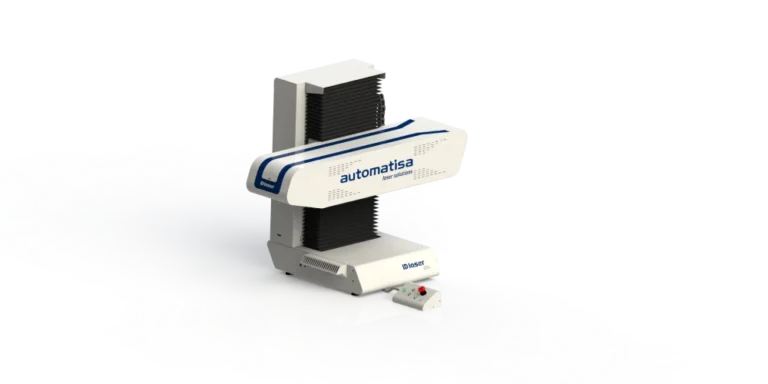

ID Laser CO2 OEM: machine for integration in production lines, it is a simple equipment to install, with the highest embedded technology;

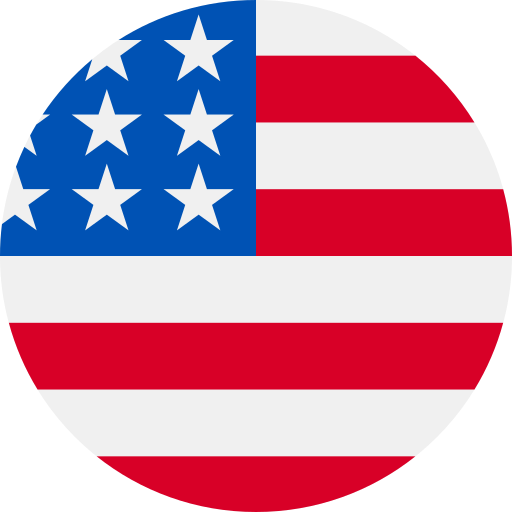

ID Laser CO2: benchtop machine, with motorized height adjustment features, in addition to great flexibility for engraving in different geometries of materials;

ID Laser CO2 with Feeder: benchtop machine, but also with an automatic roller feeding system, which allows the automatic, fast and continuous cutting of media in rolls such as labels and stickers;

ID Laser Co2 with conveyor belt: benchtop machine with automated conveyor belt for product supply, ideal for cutting and engraving delicate products that are guided precisely by the conveyor belt. All automatically and very productive.

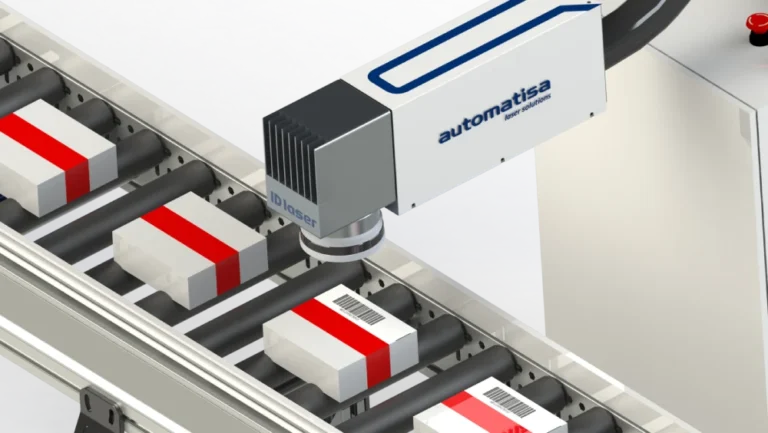

ID Laser CO2 with Matrix Feeder: CO2 laser cutting and engraving station with matrix feeder for papers, am

SPECIFICATIONS

INCLUDED ITEMS

CAN RECEIVE

| Laser Type | CO₂ |

| Available powers | 30W; 60W; 100W |

| Workspace | 110x100mm; 175 x 175 mm; 210x210mm; 300 x 300 mm (other dimensions on request) |

- Machine;

- Acrylic protection

- Operation software in Portuguese;

- Motorized Z-axis (except OEM);

- Fume extractor (except OEM);

- Cabin for electro-electronic panel;

- Installation and training service;

- Autosa Standard Guarantee.

- Computer;

- Customized protective hoods;

- Quick change tables;

- Part Rotators;

- 200 mm roll material feeder;

- Material feeder on 200 mm belt;

- Matrix feeder for adhesive;

- System Integration Services.

FREQUENTLY ASKED QUESTIONS

THE MAIN QUESTIONS

The differences are only structural, to facilitate the suitability of the client’s application, namely:

ID Laser CO2 OEM: machine for integration in production lines, it is a simple equipment to install, with the highest embedded technology;

ID Laser CO2: benchtop machine, with motorized height adjustment features, in addition to great flexibility for engraving in different geometries of materials;

ID Laser CO2 with Feeder: benchtop machine, but also with an automatic roller feeding system, which allows the automatic, fast and continuous cutting of media in rolls such as labels and stickers;

ID Laser Co2 with conveyor belt: benchtop machine with automated conveyor belt for product supply, ideal for cutting and engraving delicate products that are guided precisely by the conveyor belt. All automatically and very productive.

ID CO2 Laser with Matrix Feeder: CO2 laser cutting and engraving station with matrix paper feeder, widely used in the automotive industry for the manufacture of glass engraving masks.

It is not recommended, although it is possible. The laser cutting of materials with PVC, especially the element Chlorine, results in a hydrochloric gas, which, in addition to being toxic for the operator, causes all the metal parts of the equipment to corrode.

If your application requires cutting PVC, you must take extra care, such as using protective masks with filters suitable for operating the equipment, increasing the exhaustion of the gases produced and cleaning very frequently. Still, the corrosion process will remain. It is also important to know that electronic boards and other devices can suffer damage that are not covered by warranty policies.

As it is manufactured in Brazil, you can buy it in installments of up to 10 years, with a grace period of up to 2 years through lines subsidized by the government such as: Proger, BNDES Finame, BNDES Card. But it is also possible to acquire by leasing-type financing; financing for cash flow and working capital. These lines can finance most or all of your equipment. Our team of experts will inform you of each available alternative.

CHOOSE THE LANGUAGE

CHOOSE THE LANGUAGE