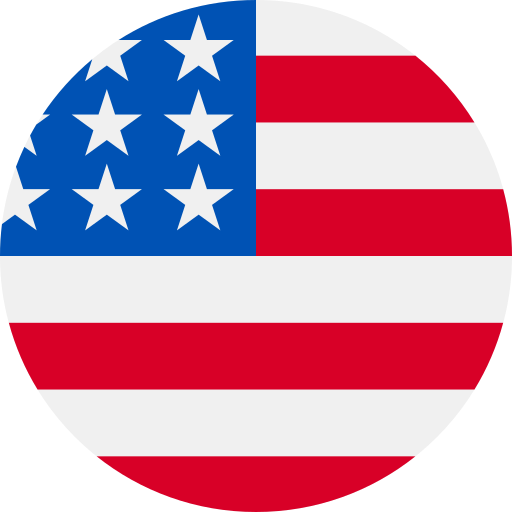

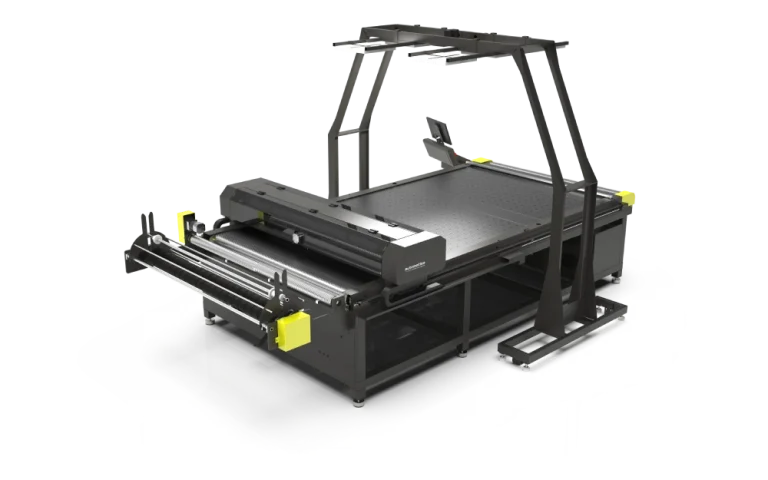

Alínea 1830

The Alínea machine is an innovation for the market for cutting printed, printed or plain fabrics. A laser cutting equipment that allows the cutting of smooth fabrics in a clean, fast, flexible way and without risk of thread pulling. In addition, when equipped with the Artificial Vision System, it makes it possible to cut fabrics after printing. This helps clothing companies not to have unnecessary inventories, in addition to drastically reducing the cost of consumables such as paper and plastic in the manufacturing process.

SPECIFICATIONS

INCLUDED ITEMS

OPTIONAL ACCESSORIES

EXCLUSIVE TECHNOLOGIES

| Laser Type | CO₂ |

| Available powers | 1 or 2 heads of 100W or 150W |

| Workspace | Up to 1800 x 3000 mm |

| performance | Travel speed up to 60m/min Position accuracy of 0.01mm Vision system accuracy of +/- 1.5mm |

- Machine;

- Operation software in Portuguese;

- Supported computer;

- Japanese servomotors;

- Galvanized mat table;

- Fabric roll feeder with sensors;

- Mechanical fabric opener;

- Under and upper extractor;

- Cooling chiller;

- Pneumatic system with coalescing filter;

- Protection according to the NR12 standard;

- Installation and training service;

- Autosa Standard Guarantee.

- Automatic fabric opener thread;

- Additional focusing lenses;

- Artificial Vision System for Large Areas;

Automated Artificial Vision System

This artificial intelligence system offers automatic image capture, processing and generation of cutting paths with accuracy of up to +/- 1.5mm in an area up to 1800 x 3000 mm. It is able to perfectly read the image of a stamped product, generate its internal and external contours or even fit a cut file automatically. It is the only solution on the market that allows localized cutting while allowing better use of space and raw material, avoiding cutting errors and loss of parts, in addition to other advantages in this cutting technique.

The VGA – Large Area Vision is a capture and image processing, with automatic generation of the cutting trajectory or geolocation of previous drawings. It captures color images of flexible or rigid materials, even if they are only 2mm thick, whether internal or external. It processes the images and generates contours in just 5 seconds, with high precision (approximately 1.5mm in the entire cutting area).

FREQUENTLY ASKED QUESTIONS

THE MAIN QUESTIONS

There are countless advantages of acquiring an Alínea, here are some more striking ones:

- The cut is clean, without marks, even on white fabrics;

- The whole process is really automatic, including capturing, processing and cutting generation;

- Capture, processing and contour generation time is very fast: approximately 5 seconds;

- Vision’s cutting system is precise, about +/- 1.5mm in relation to the edge;

- Can be operated by only one person;

- The roll change can take place without having to stop the machine;

- The mat is protected against oxidation for high durability;

- The use of fabric is the best on the market as it only requires a distance of 3mm between cuts, 2mm of printing contour;

- It is the highest displacement speed on the market: 60m/min with Japanese class A engines;

- The cutting process does not stretch or warp the fabric;

- The feeder has automated delivery with optical sensor;

- It is economical as it does not require consumables such as knives, paper and plastics in the cutting process;

- Its cut does not touch the material, allowing you to work with light and flexible fabrics and composite materials such as fiberglass;

- It has the capacity to produce up to 800 medium T-shirts per shift.

Not on Automatisa’s Alinea machine. This is because the machine was completely thought out to avoid not only any stain from cutting on natural or light synthetic fabric, but it was also thought out so that during the time of use, the dirt from the cutting residues does not migrate to the fabrics. For this, the machine’s optical system is designed to deliver an absolutely clean cut without “lips” on the edge and the equipment has a belt “cleaner” at the bottom, which prevents dirt migration.

A Alínea, além de ter um investimento inicial muito menor em relação a máquina de faca oscilante, oferece um processo de corte mais seguro para todos os tipos de tecido. O fato de que não há nenhuma ferramenta tocando o material, faz com que não exista risco de repuxo de fios ou deformações, além de não ser necessário o uso de vácuo, portanto plásticos e papéis são desnecessários, reduzindo drasticamente o consumo. Especialmente quando o corte exige encaixe em relação a uma impressão, a Alínea é imbatível, pois os recursos do Sistema de Visão são amplos e permite que tudo seja feito com alto nível de automação.

CHOOSE THE LANGUAGE

CHOOSE THE LANGUAGE